MACH 2014 – a sneak peak

7 – 11 April 2014, NEC, Birmingham

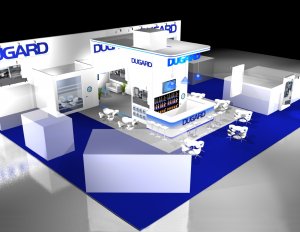

MACH2014 is looming large on the horizon so it’s time to start doing some serious work in preparation. The good news is we’re just about done with stand design and machine arrangement, now all we’ve just got to do is make sure everything falls in to place.

This year we’ve got a really interesting selection of machines – lots of new models that we haven’t seen at MACH before but are already gaining popularity from their introduction at EMO and our open house last year.

Dugard 1000E – Our new line of cost effective VMCs takes over where the Dugard ECO range left off and the Dugard 1000E will be at MACH 2014 for closer inspection. These VMCs are incredible value for money with an unbelievable build quality; they’re available in an extensive choice of bed sizes from 760mm right up to 2000mm. The 1000E comes equipped with hydraulic counter balanced head, swarf auger and spindle refrigeration as well as 10,000rpm, 24 tool twin arm ATC and 36m/min rapids. Described as “neat, tidy, sturdy and quick” the 1000E has been selling fast since we introduced it in October so make sure you come and see for yourself what all the fuss is about at MACH.

Dugard 42iT ROBO – The 42 range was first shown at MACH 2012 as well, but this time we’re bringing the 42iT ROBOT – it’s a 4 axis gang tooling lathe with a fully integrated high speed, high precision 6 axis intelligent robot. The robot can store a total of 88 programmes, it can handle work pieces of up to 6kg and can easily manoeuvre around tooling and other obstacles in the work area. It’s the first time we’ve added a robot machine to the range and this one will be a big surprise to the competition.

Dugard 65TTSY – First seen at EMO last year, the Dugard 65TTSY adds capacity to our bestselling selection of production CNC lathes. Production lathes are an increasingly important market for us – the baby of the bunch, the 32 Sub-Spindle, is our bestselling machine worldwide – so when we discovered a 65mm version was being developed we couldn’t say no. It’s a twin turret, twin spindle CNC lathe with Mitsubishi multi-axis control system, 8” and 10” chuck options and shareable Y axis delivering amazing performance for complex parts machining. It was tremendously popular in Germany, and the legend spread fast as both our stock machines were quickly snapped up at our open house in October – we couldn’t possibly leave it out on our trip to Birmingham.

Dugard HD1886B – We first showed our heavy duty boxway VMCs at MACH in 2012, but this time we’ve got a bigger model on the stand, the Dugard HD1886B. The HD range are really interesting machines, their tables have a reverse axis design reducing the footprint of each machine by 30% compared to other VMCs. This unique configuration means the table is fully supported across the full X axis movement resulting in no overhang and no X axis distortion. This space saving configuration is also available in a roller linear guide-way, a high speed spindle version ideal for mould and die machining. With BT50 spindle and 24, 32 and 40 station bi-directional twin arm ATC options on each model the HD machines are built both to perform and last, so showing the HD1886B at MACH will no doubt grow the range’s loyal following even bigger.

Dugard 1000Y Plus – As one of our best-selling machines, it’s place on the MACH stand is well deserved. It’s a VMC with a heavy duty design – optimising its rigidity, stability and accuracy – but it still has the smallest footprint in its class. It’s called the Y Plus because its Y travel is extended to 610mm. It also comes with double contact “Big Plus Tooling”, heavy duty roller linear ways, 10,000rpm spindle with refrigeration and a 24 station twin arm ATC, with all those features the popularity of the 1000Y Plus is assured for a long time to come.

Samsung PL25MC – As we’re only bringing one of our agency machines to MACH this year the PL25MC was the perfect choice – an extremely useful machine with a wide array of features, and it’s compact design fits in nicely on the stand. The Samsung range offers turning centres with 6 ~ 24” chucks, up to 3.2m between centres and mill/drill capacity as well as C & Y axes options. More specifically the PL25MC with its driven tool function can reduce manufacturing and component delivery times and aids single process manufacturing; it’s also available in 1m bed length, ideal to produce larger parts. The Samsung PL25MC always lives up to customer expectations on cost, quality and delivery so of course it was a must for MACH2014.

The Dugard stand for 2014 has a laid back sophisticated feel about it – with a cocktail bar and lots of seating for visiting customers as well as two private meeting rooms and a “snug” area at the back of the stand for a bit of extra comfort and quiet. The cocktail bar isn’t just there to look pretty, it’ll take centre stage throughout the week for customers to enjoy a cocktail – and as it’s always 5 o’clock somewhere in the world there’s no need to feel guilty about a martini or two!

At MACH we’re on stand 5630, but if you want more details on any of our MACH machines before the show email sales@dugard.com or call 01273 732286. As soon as we’ve got extra info on MACH we’ll post it on our website as well as tweet on Twitter and share on LinkedIn so why not follow us on Twitter (@dugardcom) and LinkedIn (C Dugard Ltd) to make sure you don’t miss any updated Dugard info?