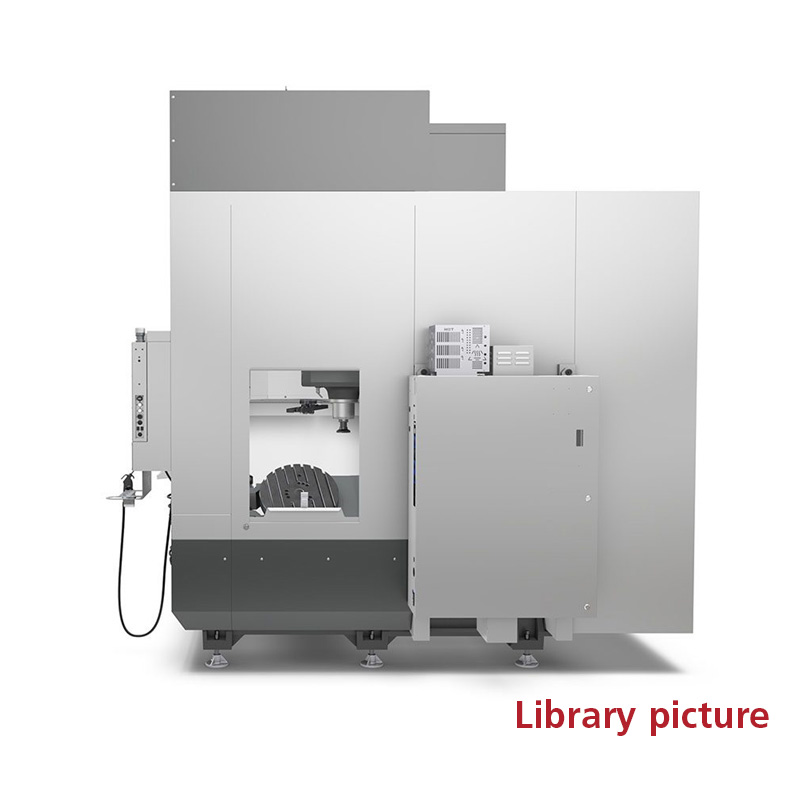

U28305 Haas UMC 750 Used 5 Axis Machining Centre

Machine Information

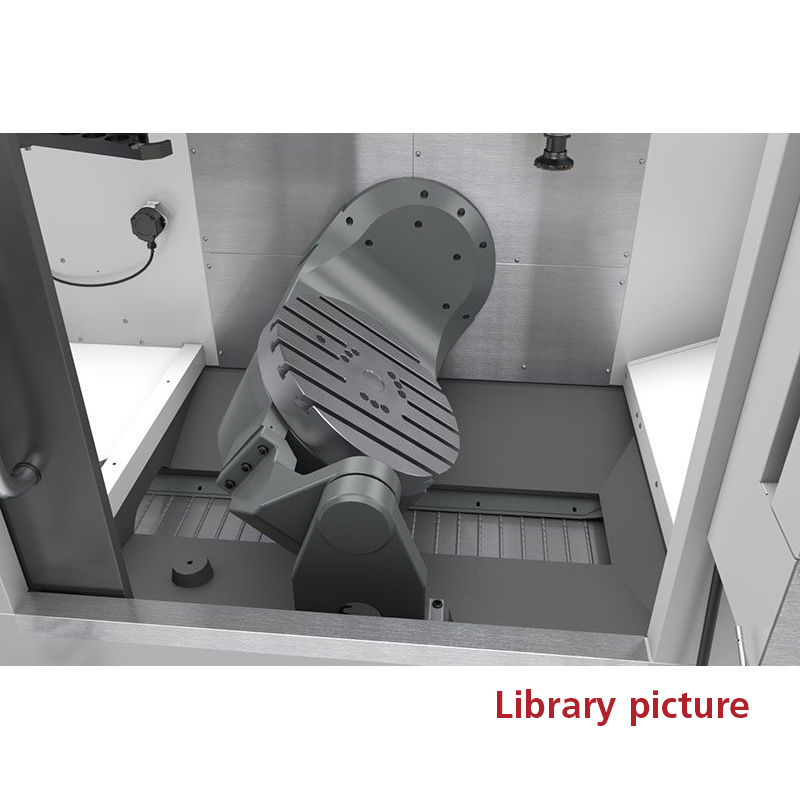

Used Haas UMC 750, a cost-effective solution for 3+2 machining and simultaneous 5-axis machining. Featuring an integrated dual-axis trunnion table, Ø500 mm platter, standard T-slots & a precision pilot bore for fixturing versatility. Trunnion provides +120° and -35° tilt, 360° rotation for excellent tool clearance and large part capacity

Machine Features

Can be seen at customer's site

A cost-effective solution for 3+2 machining and simultaneous 5-axis machining.

| 40 taper |

| 5 axis |

| 8100 rpm |

| 30+1 tool capacity |

Superior-quality CNC Machines

Made in USA

SPECIFICATION

| X axis | 762mm |

| Y axis | 508mm |

| Z axis | 508mm |

| Spindle nose to platter (~ max) | 610mm |

| Spindle nose to platter (~ min) | 102mm |

| Max spindle rating | 22.4kW |

| Max spindle speed | 8100rpm |

| Max spindle torque | 122.0Nm at 2000rpm |

| Drive system | inline direct drive |

| Spindle taper | BT40 |

| Bearing lubrication | air/oil injection |

| Cooling | liquid cooled |

| B axis travel | 120° ~ 35° |

| B axis max speed | 50°/sec |

| B axis max torque | 3037Nm |

| B axis brake torque | 2712Nm |

| C axis rotation | 360° |

| C axis max speed | 50°/sec |

| C axis max torque | 2514Nm |

| C axis brake toque | 1220Nm |

| C axis max part swing | 686Nm |

| Platter diameter | 500mm |

| Max weight on platter | 300kg |

| Max weight on platter with pallet pool | 90.7kg |

| T-slot width | 15.90 ~ 16.00mm |

| Number of standard T-slots | 7 |

| T-slot centre distance | 63mm |

| Max cutting feedrate | 16.5m/min |

| Rapids on X | 22.9m/min |

| Rapids on Y | 22.9m/min |

| Rapids on Z | 22.9m/min |

| Max thrust X | 12233N |

| Max thrust Y | 12233N |

| Max thrust Z | 15124N |

| Tool changer | SMTC |

| Tool capacity | 30+1 |

| Max tool diameter (full) | 64mm |

| Max tool diameter (adjacent empty) | 127mm |

| Max tool length (front gage line) | 305mm |

| Max tool weight | 5.4kg |

| Tool to tool (average) | 2.80 sec |

| Chip to chip (average) | 3.60 sec |

| Coolant capacity | 208L |

| Air required | 113 L/min at 6.9 bar |

| Inline air hose | 3/8" |

| Coupler (air) | 3/8" |

| Air pressure min | 5.5 bar |